-

Dairy Processing Plant

-

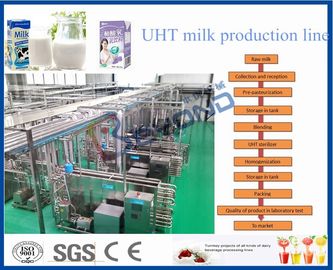

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

PLC UHT Milk Processing Line For High Temperature Pasteurized Soy Milk / Organic Milk / Milk Products

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | UHT Milk Processing Line | Function | Used For Long Shelf Life Milk |

|---|---|---|---|

| Operation | Full-auto Or Semi-auto | Shelf Life | 6 -12 Months |

| High Light | milk processing unit,milk production equipment |

||

UHT milk processing equipment long shelf life milk equipment high temperature sterilizing milk

Basic information of the line:

1. Processing line capacity: 10000L/H UHT milk;

2. Raw material: milk powder;

3. Sterilizing temperature: 137℃, holding for 5 seconds;

4. Milk outlet temperature: 30℃;

5. Finished product: UHT milk;

6. Filling machine: Aseptic pouch;

7. Storage condition: Room temperature, around 25℃.

| Flow No. | Name | Model | Unit | QTY | |||||

| A. Blending unit | |||||||||

| A-1 | Blending tank | 10000L | PCS | 3 | |||||

| A-2 | Milk pump | 20T/H | PCS | 1 | |||||

| A-3 | Milk pump | 15T/H | PCS | 1 | |||||

| A-4 | Powder and water mixer | 20T/H | PCS | 2 | |||||

| A-5 | Plate cooler | 20T/H | PCS | 1 | |||||

| A-6 | Duplex piping filter | 20T/H | PCS | 1 | |||||

| Subtotal A | |||||||||

| H. UHT Milk sterilizing and homogenizing unit | |||||||||

| H-1 | Tubular pasteurizer | 5T/H | Set | 2 | |||||

| H-2 | Full-automatic vacuum degasser | 5T/H | PCS | 2 | |||||

| H-3 | High pressure homogenizer | 5T/H | PCS | 2 | |||||

| H-4 |

Aseptic pouch |

5T/H | PCS | 4 | |||||

| Subtotal H | |||||||||

| D. Hot water unit | |||||||||

| D-1 | Hot water tank | 10000L | Unit | 1 | |||||

| D-2 | Centrifugal pump | 20T/h | Unit | 1 | |||||

| D-3 | Plate heater | 20T/h | Unit | 1 | |||||

| D-4 | Temperature control system | Set | 1 | ||||||

| Subtotal D | |||||||||

| E. Semi-automatic CIP system | |||||||||

| E | Semi-automatic CIP system | 3×3T | PCS | 1 | |||||

| R-1 | CIP return pump | 30T/H | PCS | 2 | |||||

| Subtotal E | |||||||||

| F. Auxiliary equipment | |||||||||

| F-1 | Two stages RO Water treatment system | 20T/H | PCS | ||||||

| F-2 | refrigerator unit | 100T/H | pcs | ||||||

| F-3 | Steam boiler | 2T/H | pcs | ||||||

| F-4 | air compressor | 2m³/min | pcs | ||||||

| Subtotal F | |||||||||

Plate sterilizer (UHT)

Technicals: 5℃→65℃(homogenizer)→137℃(3-5S)→20℃-25℃. This UHT system adopts ultra high heat treatment to sterilize the liquid dairy products, tea drink and juice for the the aseptic filling production; the sterilize temperature is 137℃ holding for 3~5S,by this procedure to remain the nature nutrition and flavor of the milk and juice;

This machine has the following characteristics: high heat reuse efficiency, tight structure design fine looking and temperature control well etc; discharge temperature of this machine can be self controlled so it is available for the hot filling procedure and meanwhile for aseptic cold filling;

Control styles:

full-automatic controlled

(PLC, touch screen).

![]()

![]()

![]()

Why beyond is used for aseptic processing and packaging

As an industry leader, you know that creating high-quality food is a balancing act. There is a contradiction between safety, stability, production efficiency and cost and taste, nutrition and product attractiveness. Finally, all this needs to come together.

Beyond makes it easy to find balance. Our aseptic solutions are robust and diverse with your products (even the most exquisite products!) Match the required strictness. We have helped to improve product quality and safety over the years, as evidenced by the number of machines we have in this field.

In fact, more than 50% of shelf stable foods are filled, sealed or disinfected on beyond equipment. In many markets using beyond aseptic systems (including some of the most regulated markets), there are:

Baby Food

Dairy products and dairy substitutes

Fruit juice and beverages

Oil, condiments and condiments

Pharmaceuticals

Durable equipment

It is impossible to stop production. You have prepared the raw materials, the workers are waiting to start work, and the customers are waiting for delivery. Therefore, there is only space on the floor of your factory for durable heavy equipment, which can work normally every time you power on.

We fully understand the impact of unplanned outages. That's why our aseptic filling and other processing equipment is so solid. Beyond only uses high-quality materials and advanced technology. For you, this focus on quality and detail means:

Minimal, simpler and cheaper maintenance

Minimize operational problems

Fewer and fewer work interruptions caused by operational problems